News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

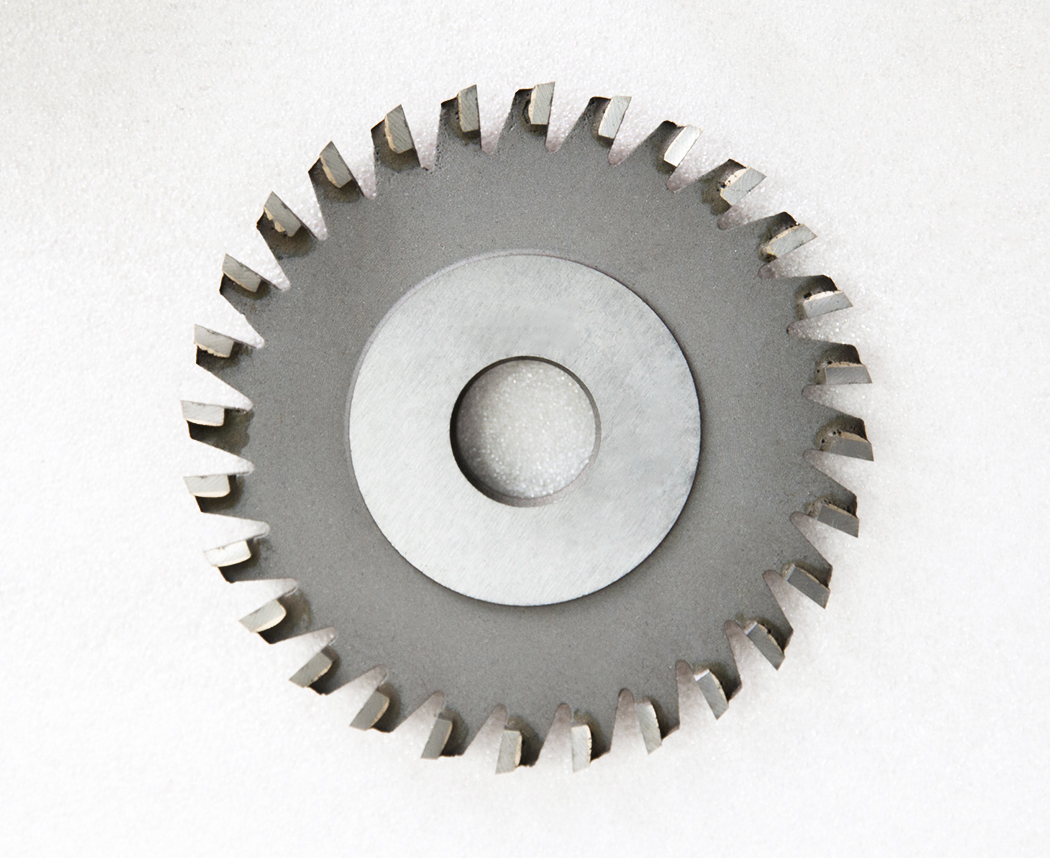

What are the main uses of three sided milling cutters with embedded teeth

A three sided milling cutter with embedded teeth is a commonly used milling tool, mainly used in the following aspects:Sources:m.dmees.cn | PublishDate:2025.04.28

1. Processing step surface: In mechanical processing, it is often necessary to process various step structures of parts. The three sided milling cutter with embedded teeth can mill the step surface through its side cutting edge, which can control the height and width of the step and ensure processing accuracy. For example, in the machining of parts such as gearbox housing and engine cylinder block, toothed three sided milling cutters are often used to machine step surfaces, providing a good foundation for subsequent assembly and use.

2. Machining grooves: For groove machining of various widths and depths, a three sided milling cutter with embedded teeth is an ideal tool. It can efficiently process grooves of different shapes such as rectangular grooves, dovetail grooves, T-shaped grooves, etc. by combining its circular and side cutting edges. In the manufacturing of machine tool workbenches, fixtures, and other parts, three sided milling cutters with embedded teeth are often used to machine various positioning grooves and installation grooves.

3. Processing plane: When a large area of plane needs to be processed, the three sided milling cutter with embedded teeth can be milled through multiple tool combinations or multiple passes. Due to its multiple cutting edges participating in cutting simultaneously, it can improve machining efficiency and achieve good flatness and surface roughness. In the flat machining of some large mechanical parts, such as the cavity plane of large molds, the installation plane of large boxes, etc., toothed three sided milling cutters have a wide range of applications.

4. Processing gear blanks: During the gear manufacturing process, a three sided milling cutter with embedded teeth can be used to process the outer circle and end face of the gear blank. By proper milling, it provides the correct positioning reference and good machining allowance distribution for subsequent gear tooth profile machining, ensuring the machining accuracy and quality of the gear.

5. Processing spline shaft: Spline shaft is a commonly used part in mechanical transmission, and a three sided milling cutter with embedded teeth can be used to process the keyway of spline shaft. By adjusting the parameters of the cutting tool and the machining process, it is possible to produce spline keyways with different specifications and precision requirements, meeting the needs of various mechanical transmissions.